The factory has two large machines that can produce products with a maximum size of 200CM

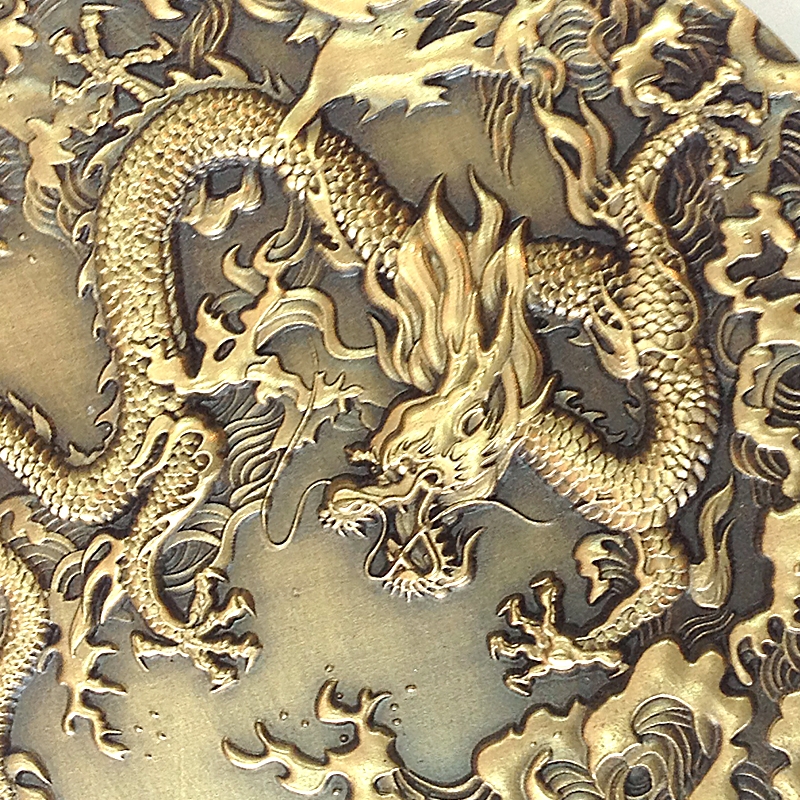

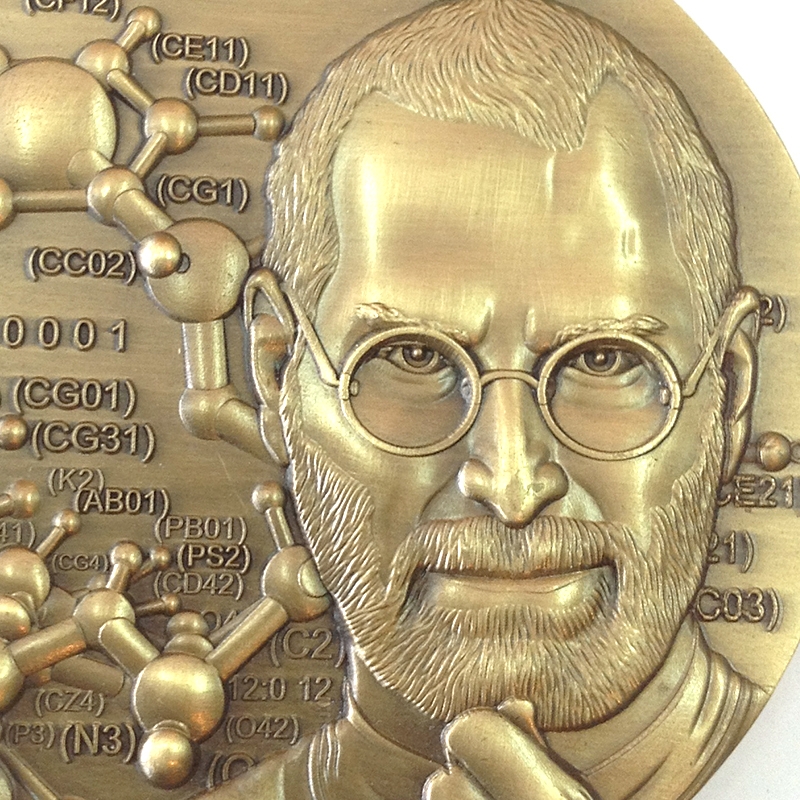

Production line: A complete production line, from design to finished products, is completed in the factory, with semi automated production lines reaching 80%

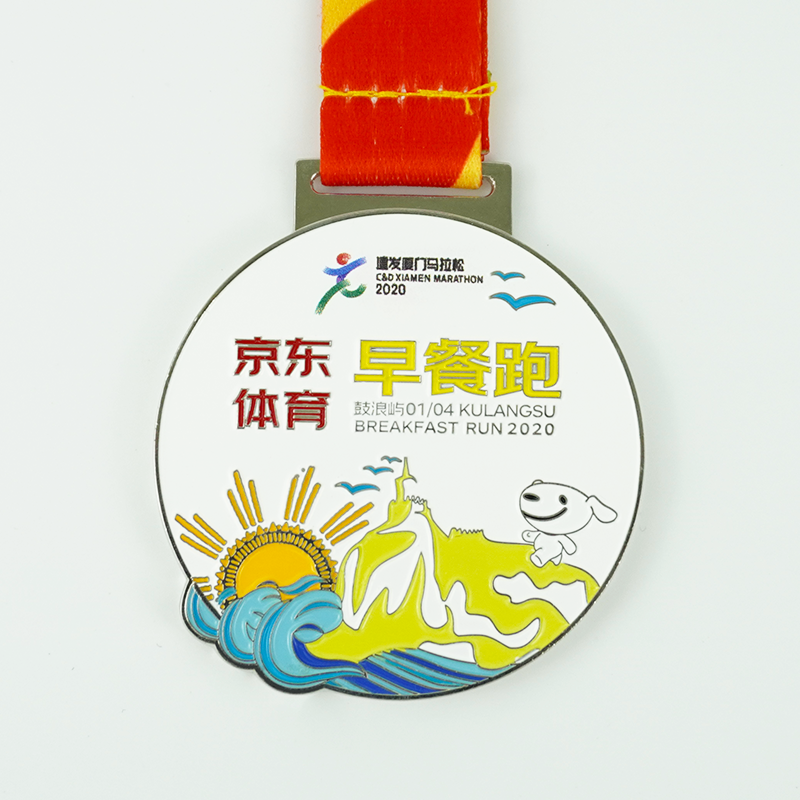

Special departments: transfer printing department, offset printing department, design department, electroplating department, printing department

Over 80 long-term cooperative clients